Environment

Air Quality

Ambient Air Quality Monitoring

Ambient air quality monitors provide an understanding of air movement patterns and air quality within the Stawell air shed, and also capture regional events affecting air quality (e.g., bush fires).

The ambient air quality monitors measure particulate matter (PM10 and PM2.5), along with trace elements (i.e., metals) in the air.

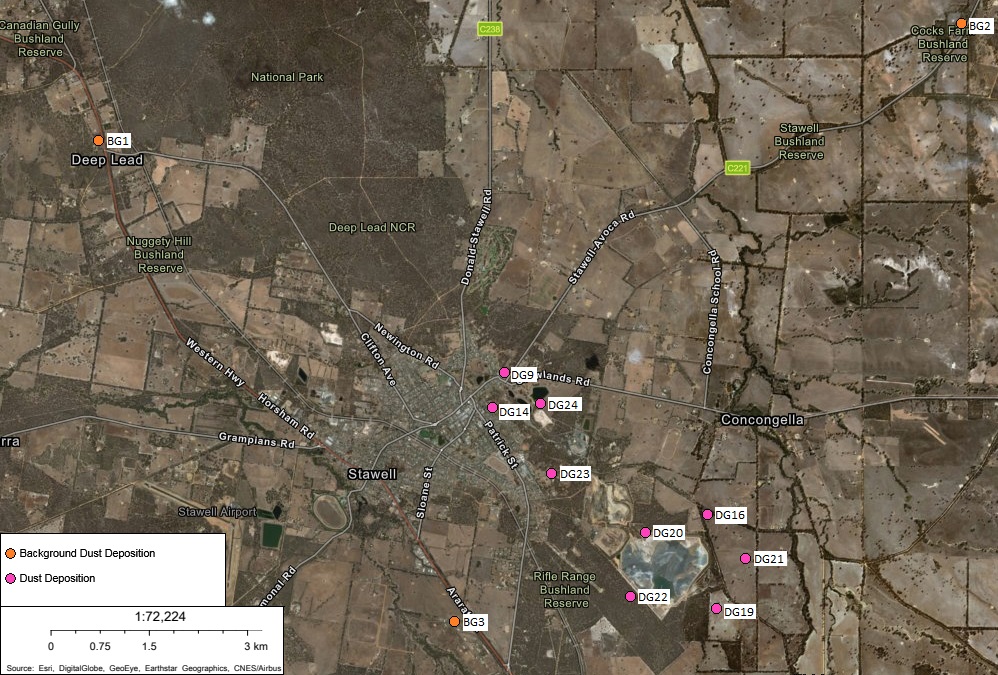

Dust Deposition

Dust deposition gauges are used to monitor localised and regional dust levels. The basis of this monitoring is to determine, over a 30 day period, the particles which settle from the air into the gauges via a funnel. This process also captures rain water and, at times, organic matter (i.e. vegetation and insects). Samples are sent for laboratory analysis to establish the quantity of total insoluble solids and other metals captured over the exposure period.

Directional dust deposition canisters are used to identify the direction from which the dust is coming from.

Gaseous Emissions Monitoring

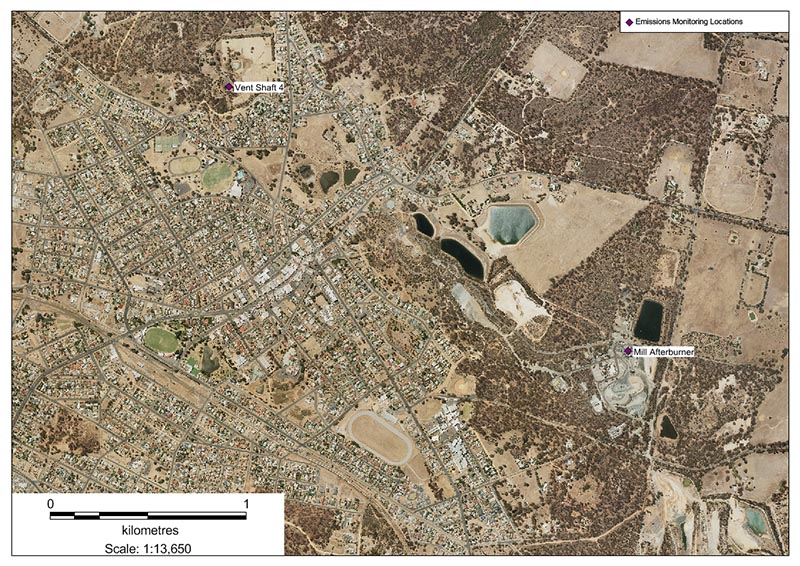

The William McLachlan Ventilation Shaft (Vent Shaft No. 4) is a critical component of SGM’s underground mine ventilation system. Fresh air enters the mine through the Magdala Portal and inlet shafts, and air is extracted from the underground mine into the atmosphere via Vent Shaft No. 4. Mining activities, such as blasting and the operation of diesel powered plant and equipment generate air emissions including nitrogen dioxide (NO2), sulfur dioxide (SO2), carbon monoxide (CO), particulates and odour. Ventilation shaft monitoring is undertaken at Vent Shaft No. 4 biannually.

Cyanide, in the form of sodium cyanide solution, is used to dissolve and separate gold from the ore in the processing facility. Hydrogen cyanide (HCN) gas can be formed under acid conditions through the conversion of cyanide ions in the slurry. SGM undertakes HCN monitoring north of TSF2, near the closest receptor . HCN emissions are monitored using HCN GasBadge detectors.

Blasting

Blasting, also known as firing, is an essential part of the gold mining process and is used in both open pit and underground mining operations. Blasting breaks or fractures the rock by using a calculated amount of explosive so that a predetermined volume of material is broken. SGM excavates the ore (gold-bearing rock) using underground trucks and loaders to transport the material to the surface for processing.

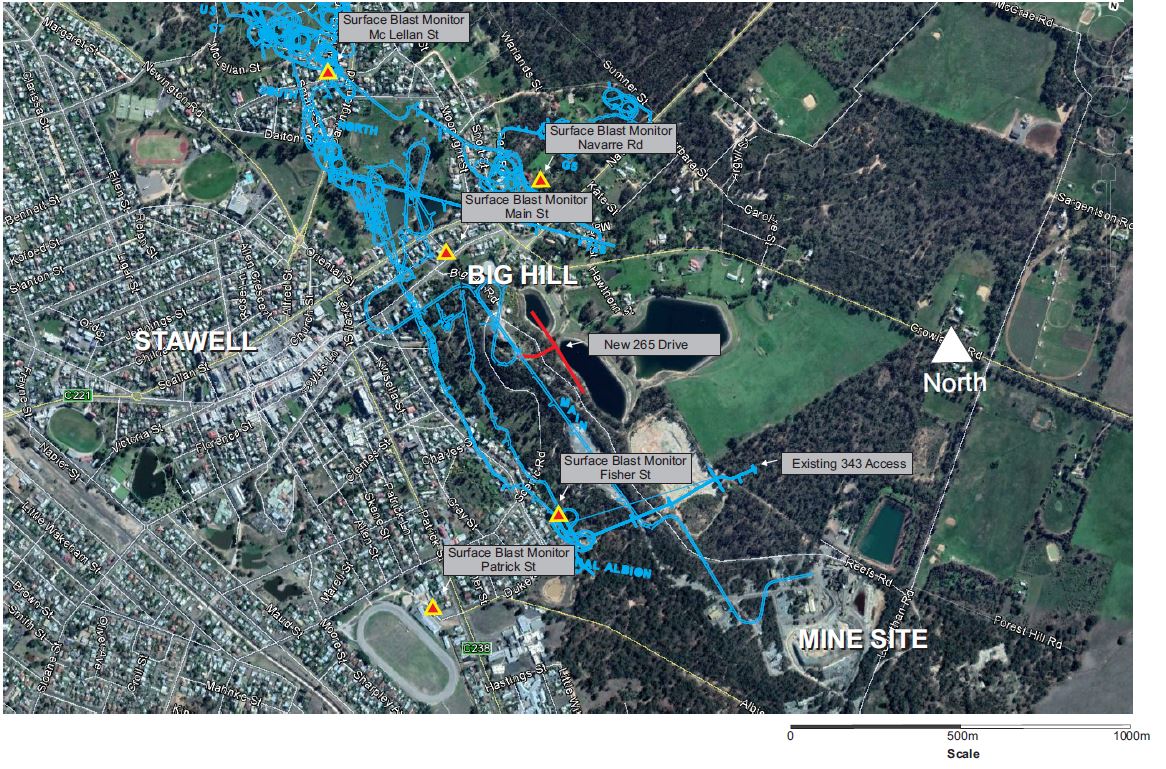

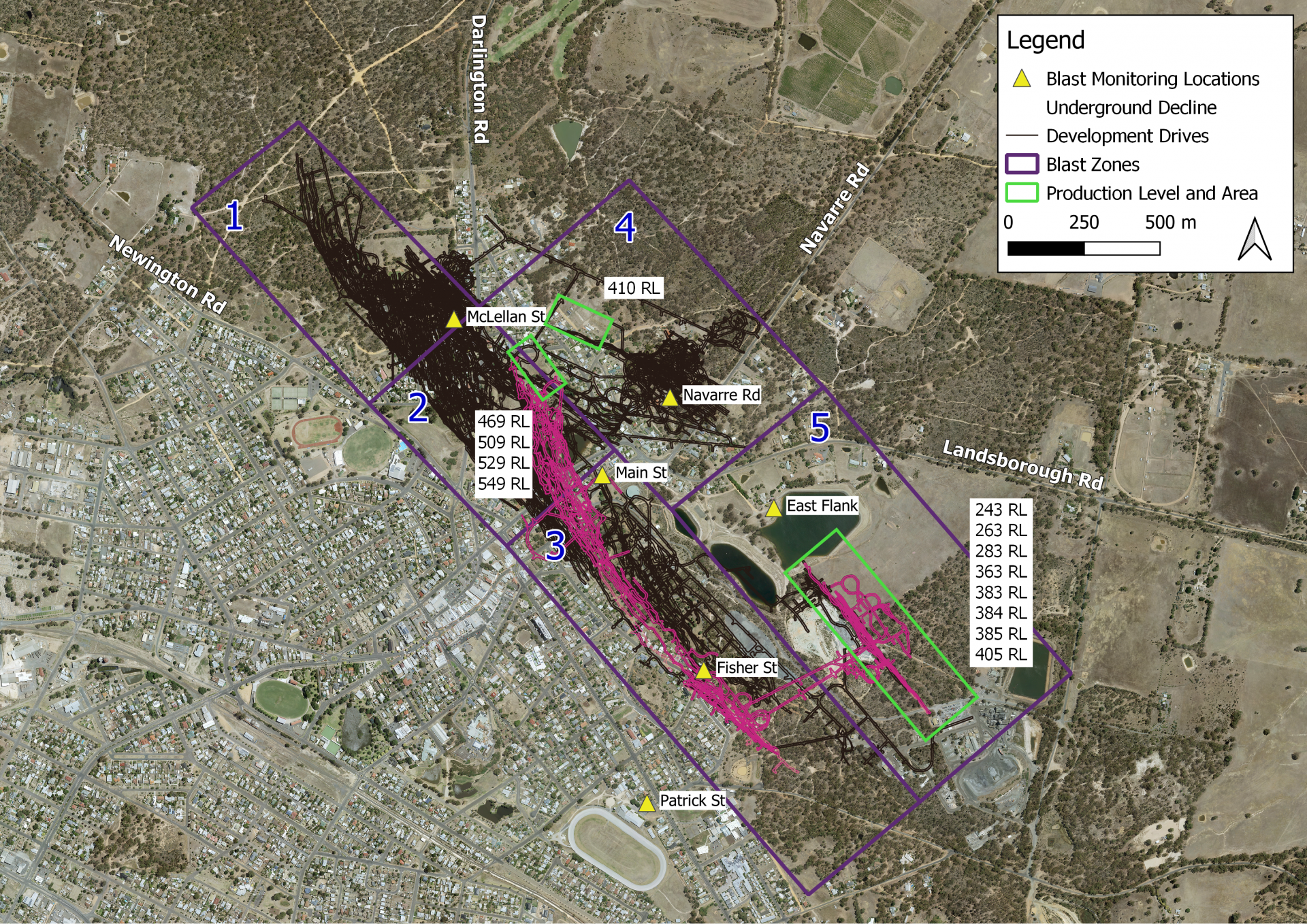

Vibration from SGM’s blasting is caused by the release of energy from the explosives as they are set off. SGM undertakes surface vibration monitoring at six locations within the Stawell township. The monitors measure peak particle velocity (PPV) in mm/s and vibration results are reviewed after every firing.

Development

Stawell Gold Mines is currently conducting development firings (or tunnelling) at 265 RL, 343 RL and 405 RL to excavate waste rock and gain access to the orebodies Bengal, Moray and Vincent. The holes are drilled in a precise pattern on the rock face, filled with explosives and detonated in a controlled manner. This method produces a small amount of rock, typically less than several hundred tonnes.

Production

SGM undertook its first production stope firing on 28 December 2018, for the first time in over 2 years in old areas on the West Flank. Underground production is focussing on areas on the West Flank while the new area on the East Flank is being developed. An important milestone occurred on the 18 April 2019 with the first firing of a stope on the 343 level in the Bengal orebody. Production will now increase in the eastern flank and development of tunnels continues to allow further access to the Bengal, Vincent and Jaguar ore bodies.

Blast Notification Text Message System

SGM offers a blast notification text message system when production blasts will occur with the date, approximate time, and the location (zone on map) of the firing. Any resident who would like to be included in the blast notification text message system is encouraged to contact Stawell Gold Mines on 03 5358 1022 or enquiries@stawellgoldmines.com.

Noise

Stawell Gold Mines operations generate noise from a range of activities, including plant and equipment operation, material handling, processing operations (i.e., milling and crushing), underground blasting, and exploration (i.e., drilling). SGM undertakes noise monitoring at four locations/sensitive receptors situated north, south, east and west of the operations area (see Figure).

Noise monitoring is conducted for a period of at least 5 minutes at three times: Day (07:00 to 18:00), Evening (18:00 to 22:00) and Night (22:00 to 07:00). Noise monitoring is undertaken by the SGM Environment Team on a quarterly basis, with the results and procedure audited and reviewed annually by an independent consultant.

Water

Groundwater

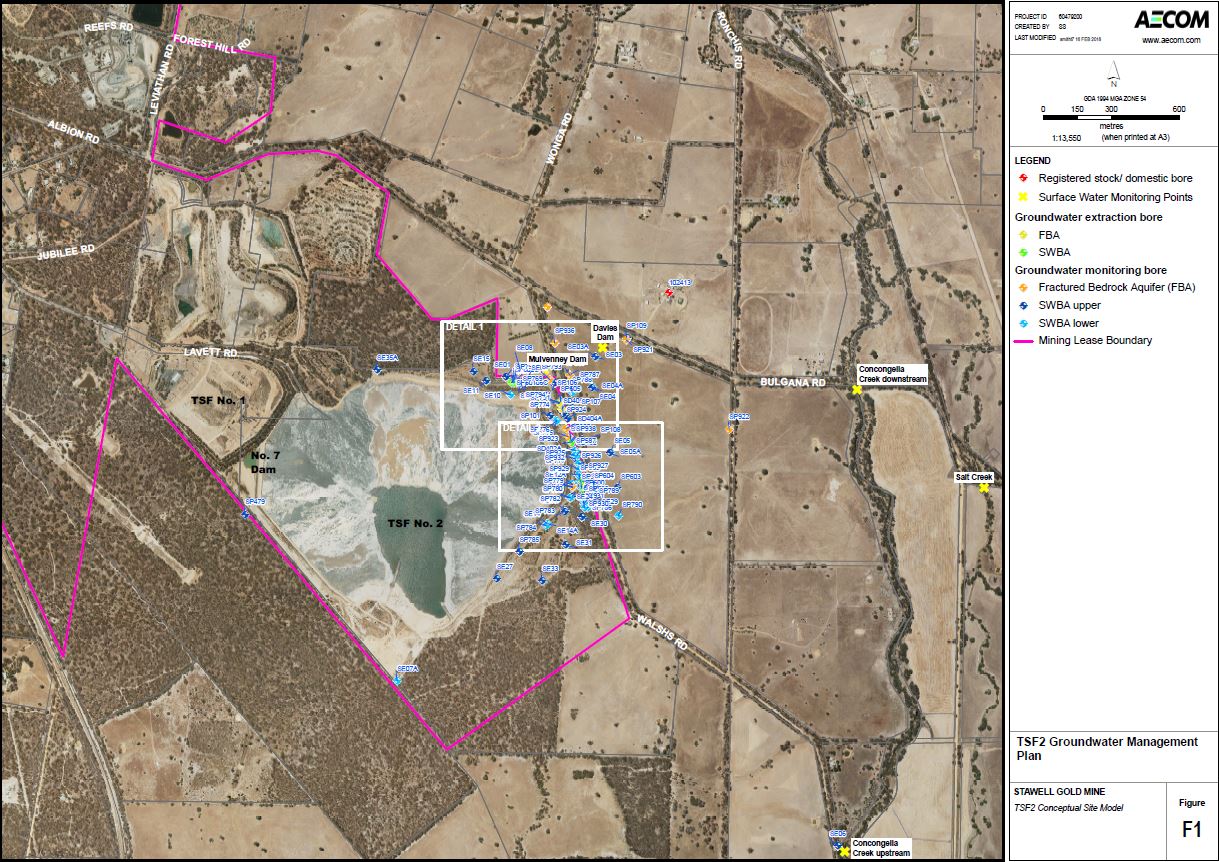

Stawell Gold Mines monitors groundwater to identify and assess potential impacts (e.g. contamination) from its operational activities (i.e. tailings storage, hazardous materials spills, water storage etc.).

Currently, SGM monitors groundwater at 25 bores located outside of the MIN5260 boundary. Monitoring bores are divided into three sampling frequencies: Quarterly, Annually or Triennially – based on the water chemistry and the determination of trend lines.

Surface Water

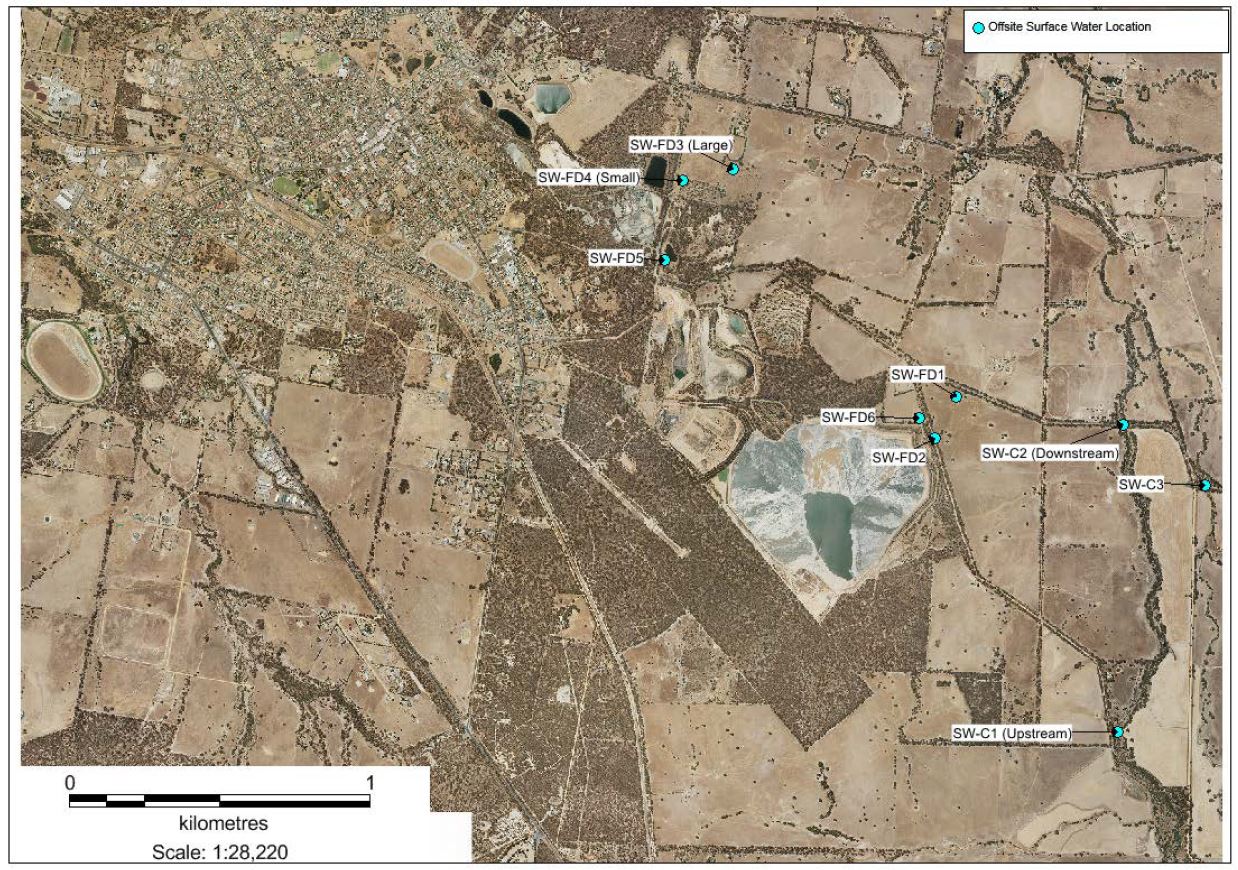

Stawell Gold Mines also monitors surface water to identify and assess potential impacts from its operational activities (i.e. tailings storage, hazardous materials spills, water storage etc.).

Currently, SGM monitors surface water at seven sites located outside of the MIN5260 boundary. Surface water sites are differentiated into creeks and farm dams.

Freeboard Monitoring

Freeboard Monitoring refers to the water storage capacity (freeboard volume) available to safely store a series of rainfall events within Tailings Storage Facility No. 2 (TSF2) at Stawell Gold Mines.

The design rainfall events (and equivalent amounts) are:

- 1 in 10 wet year 266 mm (10.4”)

- 1 in 10,000 AEP 72 hour storm event 318 mm (12.4”)

- 1 in 10,000 AEP 1 hour storm event 03 mm (4.1”)

The total rainfall (resulting from simultaneous occurrence of all three events) is 687 mm.

Following these rainfall events, a minimum freeboard of 0.6 m must be available from the top of the resultant pond and the embankment crest to prevent overtopping.

Stawell Gold Mines undertakes freeboard monitoring at TSF2 every two months, and the results are provided to Earth Resources Regulation Victoria accordingly.

Flora and Fauna

Stawell Gold Mines currently undertakes the following monitoring activities in relation to Flora and Fauna:

- Annual Ecological Assessment of the Vegetation around the Tailings Storage Facility No. 2.

- Weed Inspections and surveys to monitor the health of offset or rehabilitated areas with the aim of keeping weed presence under 5% of total cover.

- Quarterly rehabilitation photo point monitoring to establish and maintain a visual record of seasonal growth or changes at rehabilitated sites. This information is used in assisting with future planting programs and rehabilitation works.

Regulatory Notices

- Stawell Gold Mines is currently working under one regulatory notice EPA Pollution Abatement Notice (PAN) 90011650 issued on 08/10/2020 in relation to the on-going management and clean up of contamination surrounding TSF2.

- EPA Pollution Abatement Notice (PAN) 90010497 relating to the ongoing clean up of contaminated groundwater associated with Tailings Storage Facility No. 2 was revoked by the EPA on the 16/09/2020. EPA acknowledged that all actions to-date relating to PAN90010497 have been complied with and completed within the required timeframes.

- EPA Clean-Up Notice (CUN) 90009616 relating to the ongoing clean up of contaminated groundwater associated with Tailings Storage Facility No. 2 was revoked by the EPA on the 19/09/2019. EPA acknowledged that all actions to-date relating to CUN90009616 have been complied with and completed within the required timeframes.

- EPA Clean Up Notice 90008332 relating to the ongoing clean up of contaminated groundwater associated with Tailings Storage Facility No. 2 was revoked by the EPA on the 21/08/2018. EPA acknowledged that all actions to-date relating to CUN90008332 have been complied with and completed within the required timeframes.

Please refer to the current ERC Meeting Minutes for further information on the Clean Up Notice.